All-round protection for the urea system

In construction and agricultural machines, urea filters are required to offer high performance as they are subject to high workloads. In order to better meet these special requirements, MANN+HUMMEL has developed a new, compact urea filter module.

MANN+HUMMEL urea filter module for construction and agricultural machines

MANN+HUMMEL urea filter module for construction and agricultural machines

At the latest after the introduction of the Tier 4 and Euro 4 emission standards the situation is clear: the treatment of exhaust gas now requires some ingenious solutions. Selective catalytic reduction (SCR) systems used in off‑highway vehicles now face new challenges. It is not sand in the transmission, but dust from the environment which the manufacturers of construction and agricultural machines find difficult to cope with. For example, the urea solution used to clean the exhaust gas of these kind of systems becomes more quickly contaminated, possibly due to filling up the tank in a contaminated environment or because the SCR tank is not sufficiently aerated and ventilated. At the same time, the thermal management requirements are increasing. The patented urea filter module from MANN+HUMMEL was developed to ensure the best possible starting time for the SCR system, robust operation, well-coordinated service intervals, and efficient protection for the feed pump.

Venting with suction-side operation

Installation position of the MANN+HUMMEL urea filter module for construction and agricultural machines

Installation position of the MANN+HUMMEL urea filter module for construction and agricultural machines

Depending on the customer requirements, the filter module can be fitted on the suction side upstream or on the pressure side downstream of the SCR unit and is easy and flexible to connect. For example, the filter can be positioned outside of the urea tank at a more accessible location to enable quick and easy access during servicing. The requirements for suction-side urea filters are high, whereby if the pressure inside goes below the ambient pressure, air trapped inside the urea solution will be released and then collect in the upper part of the filter housing. The result is that the liquid level in the filter system goes down which leads to less liquid flowing to the filter surface area and ultimately the SCR system will fail.

Using a patented venting membrane, the experts at MANN+HUMMEL have come up with the solution. The hydrophobic surface of the membrane prevents a wetting with urea solution. This enables air to be continually directed away to the clean side. The design of the membrane is mainly determined by sensitivity to air and the critical system pressure of the SCR system. If this pressure falls below a critical level, an error message is generated and the system switches off. At MANN+HUMMEL, experts use an own test bench operating with different conditions to exactly select the venting membrane which corresponds to the customer requirements. The aim is to perfectly match the dirt holding capacity of the complete system to the respective application.

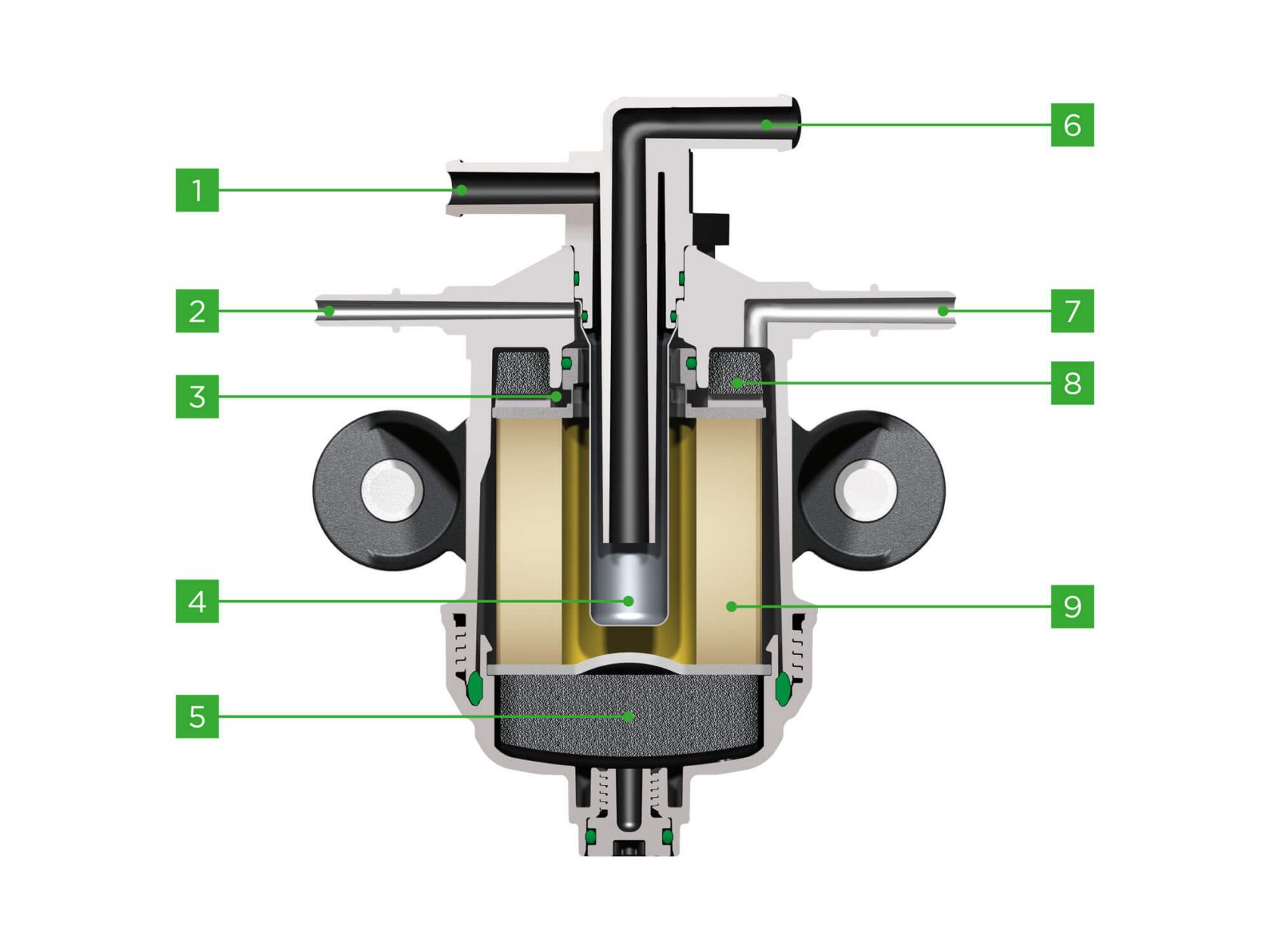

Structure of the urea filter module

Structure of the urea filter module

1 Coolant outlet

2 Urea outlet

3 Venting membrane

4 Hydraulic heater

5 Compensation element

6 Coolant inlet

7 Urea inlet

8 Compensation element

9 Filter element

Reliable function at low temperatures

Thermal management represents a further challenge for urea filters. As construction and agricultural machines are frequently used in cold regions, the urea solution can freeze in the filter and in the process expands due to the high water content. The resulting compressive forces on the filter housing are reduced to a minimum by compensation elements developed by MANN+HUMMEL which are made from EPDM foam and protected by a patent.

But the creativity of the filtration experts was not limited to the venting and mechanical stress on the housing. The experts were also creative in terms of heating. According to the current exhaust gas treatment standard, SCR systems have to be ready for operation within a certain time after the engine is switched on. The urea solution in the filter therefore has to be defrosted as quickly as possible. In this respect, MANN+HUMMEL offers two solutions with either an electric or a hydraulic heater. The electric heater quickly reaches the require temperature because it achieves full output immediately when the engine is started. The hydraulic heater, on the other hand, needs longer but does not require electrical power which is an additional burden for the electrical system during a cold start. Depending on the machine version, hydraulic heaters are more suitable due to their economic advantages.

The urea filter module allows MANN+HUMMEL to take a big step towards sustainable filtration. The experts have found a flexible and self-sufficient filtration solution which makes an important contribution towards the perfect protection of SCR systems in order to help meet the exhaust gas standards of today and the future. This was recently recognized by a well-known, US company in the area of agricultural machines. In future, the customer will equip his vehicles with engines above 4.5 liters engine capacity with the compact filter module from MANN+HUMMEL.